railroad spike

- Size: all types

- Standard: GB, DIN, ISO, ANSI/ASTM, B7, BS, JIS etc

- Surface: plain or as customer requirement

- Packing: bulk in carton, then on pallet, or according to customers

Railroad spike for sale

Railroad spike, also know as rail spike. Railroad spikes are designed to maintain gauge between the running rails and also they are mean to secure the steel rail to the railroad tie. Rail spikes have various shapes serving for different functions. The materials for railroad spikes production can be carbon or stainless steel based on the requirement, and the surface of the spikes can be plain, black, hot dipped galvanized, or sherardized, etc. Among the various railroad spikes, dog spikes and the screw spikes are the most common types.

Specifications of rail spikes:

- Name: railroad spike or track spike

- Grade: 4.8

- Material: carbon steel

- Length: 80mm-165mm or non-standard as requested

- Non-standard OEM is available if you provide a drawing or sample.

- Samples are free.

Dog spikes - a type of railroad spike

The dog spike is used to fasten T-shaped rail road track to wooden ties, which has an L-shaped head and square shank, and the underside of whose head is sloped to fit the top surface of the rail base. Spikes with various sizes are provided to meet the different requirements of penetrating length of spikes. The common track spikes are the 5/8”*6” and the 9/16”*5-1/2” for smaller rail sections, and they are usually secured in either 200 lb. kegs or 50 lb. kegs.

| Specification | Material | Surface | Standard |

| 5/8*6 '' | A3,Q235, 45#,55#, etc | According to customer needs. |

According to customer’s drawings or samples.

|

| 9/16*5-1/2 '' | |||

| 3/8''*3-1/2 '' | |||

| 1/2*3-1/2 | |||

| Other kinds |

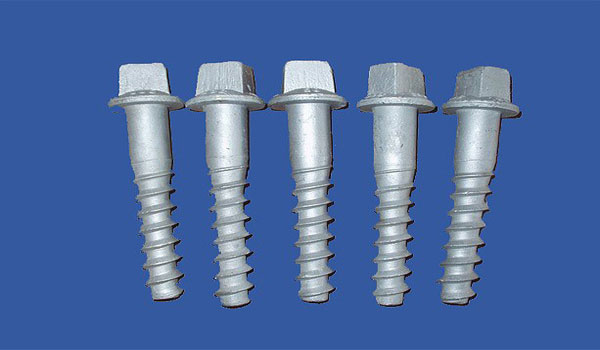

Screw spikes - a kind of railroad spike

Railway screw spikes are usually used to fasten railway ties or sleepers and also they also can be used in conjunction with plastic ferrules, casted into concrete ties /sleepers. Rail screw spikes can be various in thread profiles, lengths, diameters and drive heads based on specific geographic requirements.

Ss series Sleeper Screw

Ss series sleeper screw is one of our hot sales, with different dimensions as shown below

| Type | Specification | Weight/kg | Surface | Standard |

| Ss 1/130 | M22*130 | 0.451 |

Natural

Zinc

Paint

Oil

According to your needs.

|

UIC

AREMA

GB

or

According to your drawings or samples.

|

| Ss 1/150 | M22*150 | 0.478 | ||

| Ss 2/180 | M22*150 | 0.595 | ||

| Ss 5/150 | M24*150 | 0.545 | ||

| Ss 6/150 | M26*150 | 0.702 | ||

| Ss 7/180 | M24*180 | 0.636 | ||

| Ss 8/140 | M24*140 | 0.528 | ||

| Ss 8/150 | M24*150 | 0.548 |

Square head screw spike

|

Type

|

Specification

|

Material | Surface |

Standard

|

| Square head screw spike | M22*145 |

45#

55Q

Q235

or

According to your needs.

|

Natural

Zinc

Paint

Oil

According to your needs.

|

UIC

AREMA

DIN

GB

or

According to your drawings or samples.

|

| M22*155 | ||||

| M22*165 | ||||

| M22*185 | ||||

| M22*195 | ||||

| Other kinds |

Hexagon screw spike

Hexagon screw spike includes several different sizes such as:M22*145, M22*155, M22*165, M22*185, M22*195, and so on.

| Grade | 4.6 | 5 .6 | 8.8 | 10.9 |

| Material | Q235 | 35# | 45# | 40Cr |

| Mechanical | Tensile strength: ≥ 400Mpa | Tensile strength: ≥ 500Mpa | Tensile strength: ≥ 800Mpa | Tensile strength: ≥ 1000Mpa |

| Yield strength: ≥ 240Mpa | Yield strength: ≥ 300Mpa | Yield strength: ≥ 640Mpa | Yield strength: ≥ 900Mpa | |

| Elongation: ≥ 22% | Elongation: ≥ 20% | Elongation: ≥ 12% | Elongation: ≥ 9% | |

| Cold bending: 90 degree | Cold bending: 90 degree | Cold bending: 90 degree | Cold bending: 90 degree | |

| without crack | without crack | without crack | without crack | |

| Surface | plain (oiled) , Oxide black, Zinc, HDG, wax, bitumen, Dacromet, Sherardizing | |||

Double-head screw spike

The two-end-head screw spike is always used with Nabla clip fastening system, especially popular used in Africa. To meet the strict bending requirement, special raw material is applied by straightening it without any crack after bending 30 degrees or even more.

- Specifications:

- Size: 23×174

- Grade: 4.6, 5.6, 8.8, 10.9

- Raw Material: 35#

- Raw material: Q235, 35#, 45#

- Surface Treatment: Plain (oiled), Bluing, Zinc, HDG, etc

Manufacturing Process for screw spike:

Raw Material→Wiredrawing→Rod Cutting→Head Forming→Edge Cutting→Thread Rolling→Heating Treatment→Surface Treatment→Final Inspection→Packing→Shipment

Comparison of dog spikes and screw spikes

Firstly, the screw spikes provides more than twice of the holding power than that of the dog spikes. Secondly, The production cost of a screw spike is higher than that of a dog spike or dog nail. Thirdly, a screw spike can also be used together with a spring washer. No matter it is a dog spike or a screw spike, it will be the best spike, if it is used in the right place. For more information regarding the differences, please read this post.

- Rail Fasteners

- rail fastening system

- rail clip

- railroad spike

- Track bolt

- rail shoulders

- rail anchor

- rail clamp

- tie plate

- Rail Pad

- rail insulator

- rail plastic dowel

- other rail fasteners

- Railway Switch

- SKL series rail fastening system

- Chinese standard rail fastening system

- screw spikes

- Crane rail fastening system

- K type rail clip for Africa

- Hey-Back Rail Fastening

- rail fasteners for Mexican market

- Ss25 screw spike

- Ss35 rail sleeper screw spike

- Ss8 screw spike

- coach screw

- Crane Rail Clip

- Rail Joints (Fishplate)

- Steel Rail

- Railway Sleeper

rail clip

rail clip

rail joints

rail joints

Español

Español English

English