Analysis of Rail Fastening System: Part1

Rail fastening system, also known as rail fasteners, is components that connect steel rails and railway sleepers. It plays an important role in ensuring track stability and reliability. At present, 90% of the under-track foundation of the Chinese railway's main track is a concrete structure. With the development of passenger dedicated lines and heavy-duty transportation, the requirements for the performance of rail fasteners have been improved. At the same time, countries around the world use different standard rail fasteners, such as the German vossloh, the British Pandrol, and so on.

As a professional railway fastener supplier, we will comprehensively analyze the current situation of rail fastening system and the main problems, explain the basic requirements of rail fastening system, and introduce the technical characteristics of rail fasteners in various countries. For the convenience, we will divide into two parts to introduce railway fasteners including Chinese standards and other international standard railway fastening system. Today we will study Chinese standard rail fasteners firstly.

Chinese standard rail Fastening System

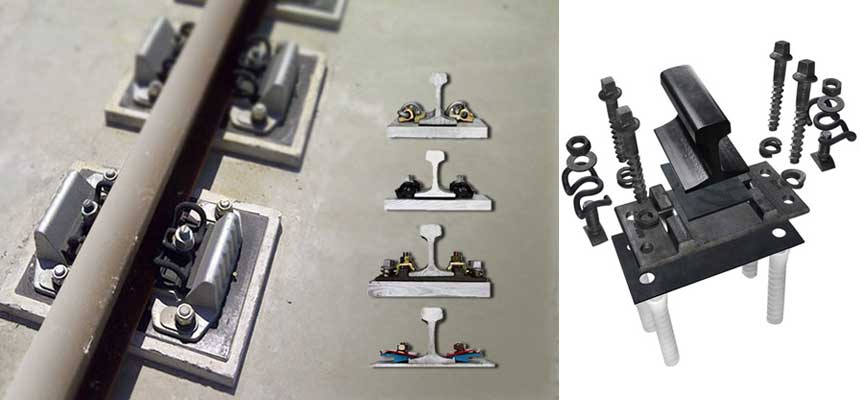

The rail fastening system mainly consist of rail clips, rail pad, tie plate, screw spike, plastic dowel, rail shoulder and etc. China's rail fastening system mainly include type I, type II and type III. Type I and Type II fasteners are bolted with shoulders. During the use of rail fastening system, the I-type rail fastening system have small strength and safety reserves, relatively insufficient buckle pressure, and damage of rail clips. Type I rail fastening system is replaced by type II. The type II rail clip fastening system is widely used in the railway line now. Type II rail fasteners were developed from the Type I rail fasteners, except that the rail clips were redesigned with new materials, and the remaining components were common to Type I rail fasteners.

The type III rail clip fastening system is boltless and non-shoulder fasteners and currently being laid in large numbers. However, the type III rail fastener basically does not have the function of adjusting the rail gauge and the height of the rail surface, and it is limited in use. At present, all types of concrete sleepers are required to be laid in the speed-increasing section. Because of the different fasteners, they are divided into III a and III b sleepers, III a concrete sleepers are equipped with type II rail fasteners, and III b concrete sleepers are used with type III rail fasteners. .

Under the repeated load of the rolling stock, the basic line under the concrete track bed will be subjected to great impact and vibration. Due to the high rigidity of the concrete track bed, excessive load bending moment will cause damage to the under-rail foundation. For vibration absorption and reduction, an elastic cushion must be laid between the rail and the foundation. The elastic cushion can reasonably distribute the impact vibration energy to the various fasteners of the track, and the working condition of the rail fasteners can be improved. At the same time, the elastic cushion layer can make the track have electrical insulation properties on the track.

Common problems of rail fasteners

Insufficient fundamental research

The complexity and randomness of the wheel-rail relationship determine the strict requirements on the track structure. The track structure consists of the steel rail and sub-rail foundations, and they are fastened by rail fastening system. Therefore, the performance of each component of the rail fastening system is closely related to the track structure. Chinese rail fasteners focus on the research of each component, but not a whole structure. For example, the fasteners of Germany, France, Britain and other countries are treated as a system, the performance of each component of the rail fastener is coordinated and matched, for adapting to the dynamic requirements of the wheel-rail.

Unreasonable structure of rail fastening system

The structure of rail fastening system should meet the requirements of the wheel-rail dynamics from the view of the track structure components. Each component of the rail fasteners should have a reasonable structure and accurate dimensions. The assembly should be compact, reasonable force. Taking the type III rail fastener currently designed in China as an example, the structure of the embedded part is thick, the section is abrupt, the stress is concentrated, the structure is obviously unreasonable, and the fixing quality of the embedded part is unreliable, which affects the assembly quality. The rail fasteners of the concrete sleeper are pre-buried by rail plastic sleeve. The results show that the nylon sleeve and rail bolt combination has a bad performance.

Poor quality of product manufacturing

The poor quality of the products is mainly acted as following aspects: First, the technical standards are low, the design ideas are backward, and the dimensional tolerances are too large. For example, the structure design of the III type rail fastener is unreasonable, and the pre-embedded material does not use the ductile iron in the original standard, and a large number of fasteners are loose and the buckle pressure is insufficient. Second, assembly and cooperation cannot meet the requirements of use, such as the embedded method of embedded parts affecting assembly accuracy. The third is to shoddy and counterfeit in the supply.

Single variety of fasteners

Different track structures use rail fasteners that match their performance. Different rail fastener systems should be used for the main track, the ballast track and the ballastless track, the track on the roadbed and the track on the bridge. However, the variety of Chinese standard rail fasteners is single and cannot meet the needs of different track structures.

- Rail Fasteners

- rail fastening system

- rail clip

- railroad spike

- Track bolt

- rail shoulders

- rail anchor

- rail clamp

- tie plate

- Rail Pad

- rail insulator

- rail plastic dowel

- other rail fasteners

- Railway Switch

- SKL series rail fastening system

- Chinese standard rail fastening system

- screw spikes

- Crane rail fastening system

- K type rail clip for Africa

- Hey-Back Rail Fastening

- rail fasteners for Mexican market

- Ss25 screw spike

- Ss35 rail sleeper screw spike

- Ss8 screw spike

- coach screw

- Crane Rail Clip

- Rail Joints (Fishplate)

- Steel Rail

- Railway Sleeper

rail clip

rail clip

rail joints

rail joints

Español

Español English

English