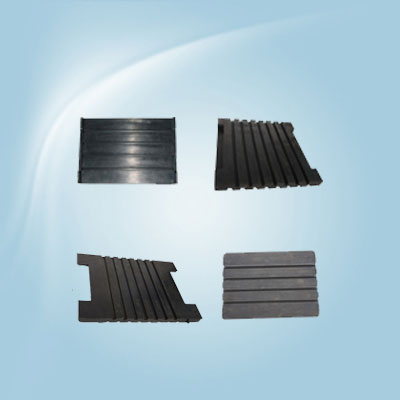

Rail Pad

- Size: custom types

- Standard: E-type, SKL, KPO, NablaPR, Russia, fast, UIC, BS, JIS,etc.

- Surface: customization

- Packing: according to requirements

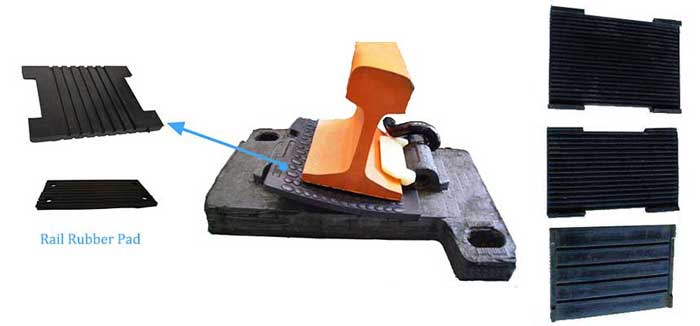

Rail pads are elastic polyurethane mats which are interposed between steel rails and railway sleepers to protect the sleeper top from wearing and impacting.

The starting stiffness of a rail pad is designed to not be high so that their relative deformation under the spring clip toe loads is greatly substantial. In this way, it can guarantees the rail pad maintaining in close contact with the rail despite of any vertical movements of the latter. In addition, the reason why rail pads made up of rubber or plastic is to dampen the shocks of vibration of a passing train.Rail pad functions

A rail rubber pad is essential in reducing shock and vibration in a rail system. The pad laid under the rail to ensure:

- Load distribution over a larger surface

- Elimination of load concentration and the resultant fatigue stresses

- Centering of loads on the supporting element

- Absorption of uneven contact surfaces between rail and support

- Reduction of noise and vibration

- Sealing between the bottom of the rail and the top of the support

- Reduction of wear of the rail and its support

Rail pad materials

We have developed a range of high-performance elastic rail pads for stiffness requirements and various application areas-from trams through standard gauge railways to heavy haul lines, especially those for E-type rail fastening systems and SKL type rail fastening systems with material of HDPE/EVA/Rubber, with following properties respectively.

| Technical Parameter | Unit | Technical Requirement | Value |

| Density | g/cm3 | 0.95-0.98 | 0.95 |

| Tensile Strength | Mpa | ≥19 | 19 |

| Elongation | % | >80 | 150 |

| Melting Point | ℃ | 170-190 | 190 |

| Insulation Resistance | Ω | ≥1×1010 | 3.5 ×1010 |

| Hardness | A | ≥98 | 98(A) |

| Technical Parameter | Unit | Technical Requirement | Value |

| Density | g/cm3 | 0.95-0.98 | 0.95 |

| Tensile Strength | Mpa | ≥15 | 16 |

| Elongation | % | >500 | 550 |

| Melting Point | ℃ | 170-190 | 170 |

| Insulation Resistance | Ω | ≥1×1010 | 5.0 ×1010 |

| Hardness | A | ≥90 | 92(A) |

| Technical Parameter | Unit | Value |

| Stiffness | KN | 90-130 |

| Hardness Shore A | ℃ | 72-80 degree |

| Electronic Resistance | Ω | ≥ 106 |

| Tensile Strength before Aging | Mpa | ≥12.5 |

| Elongation before Aging | % | ≥250 |

Rail pads classifications

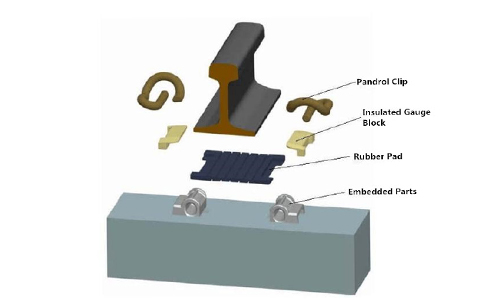

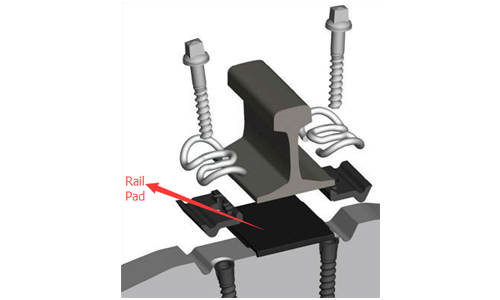

Rail pads for E-type rail fastening systems

Rail rubber pads used for E-type rail fastening systems are with the similar functions of the rail insulators to insulate the rail above it from the tie sleepers lied below it, for effective protection against vibration and structure-borne noise as well. The rail pad works together with e-clips, rail insulators/insulated gauge blocks and rail shoulders/embedded parts to form a whole set of E-type rail fastening system.

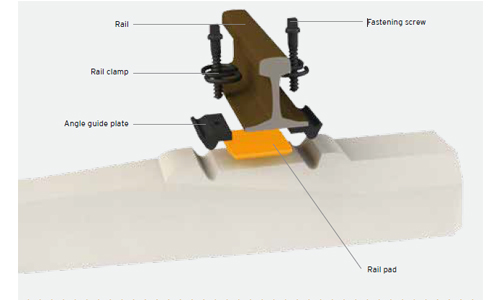

Rail pads for SKL rail fastening systems

A rail pad in a SKL rail fastening system is a small but crucial fastener part, working together with SKL clips, screw spikes, plastic dowels, guide plates and so on. The elastic rail pads we produce possess a defined stiffness and demonstrably increase the elasticity of the track superstructure. With a higher level of elasticity, it contributes towards quiet running of the rolling stock, to meet today’s acoustic requirements on railway lines.

Rubber rail pads for concrete sleepers

| Material: | rubber |

| Standard: | TB/T2626-95 |

| Application: | 43kg/m ,50kg/m, 60kg/m, 75kg/m rail |

| Models: | 43-7-7, 43-10-7, 50-7-9, 50-10-9, 60-10-17, 60-12-17 |

| Operation temperature: | -50~70 degrees |

| Certificate: | ISO9001:2008 |

| Notes: | Should be stored in clean, ventilated place. Don’t put under direct sunlight, and keep away from heat sources and chemical reagents. Don’t touch oil, organic solvent and other chemicals. |

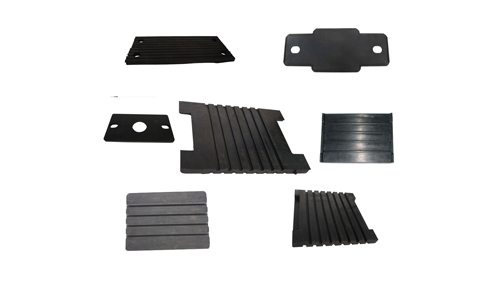

High-elastic grooved EVA/HDPE/rubber rail pads

Our EVA/HDPE/rubber rail pads are with high elasticity, applying to types for rails such as rail UIC54, UIC60, BS80lbs,BS100lbs, and sizes as ordered. The pads can be customized with or without grooves, in various possible designs, depending on customers’ requirements.

- Rail Fasteners

- rail fastening system

- rail clip

- railroad spike

- Track bolt

- rail shoulders

- rail anchor

- rail clamp

- tie plate

- Rail Pad

- rail insulator

- rail plastic dowel

- other rail fasteners

- Railway Switch

- SKL series rail fastening system

- Chinese standard rail fastening system

- screw spikes

- Crane rail fastening system

- K type rail clip for Africa

- Hey-Back Rail Fastening

- rail fasteners for Mexican market

- Ss25 screw spike

- Ss35 rail sleeper screw spike

- Ss8 screw spike

- coach screw

- Crane Rail Clip

- Rail Joints (Fishplate)

- Steel Rail

- Railway Sleeper

rail clip

rail clip

rail joints

rail joints

Español

Español English

English