Crane Rail Clip

- Size:Full rail clip dimension available

- Standard:Bolted crane rail clips, Welded crane rail clips

- Surface:Hot-dip galvanizing, painting,galvanized,coating

- Packing:Woven Bag/Kegs and Pallet/wooden box or upon customers

Bolted Crane Rail Clip

Bolted crane rail clips are a kind of very frequently used rail clips, and they are widely used in all types of crane and heavy equipment rail fixing systems. They fix the track firmly on the foundation structures mainly by using bolts to ensure the rails' stability and safety. Compared with welded crane rail clips, bolted crane rail clips’ installation is easier and more flexible in moving and disassembling, convenient for maintenance, but their bearing capacity is slightly inferior to welded crane rail clamps.

Bolted crane rail clips applicable scene:

-

Heavy-duty cranes: Suitable for heavy-duty equipment, such as overhead cranes, goliath cranes, etc. can provide powerful braced force.

-

Ports and terminals: Suitable for port cranes, ensure the tracks remain stable in the moisture and corrosion environment.

-

Industrial environment: Widely used in steel mills, mines, warehouses, etc. industrial environment, adapts high capacity and frequency of using requirement well.

- Temporary rail system: Such as temporary construction track, movable crane equipment, etc.

Bolted crane rail clips advangtages:

-

High strength fixation.

-

Strong bearing capacity.

-

High wear resistance: Adopt wear-resistant material, like a worn shaft, in its structure, helping to reduce abrasion between the track and clips which lengthens the equipment’s service life.

-

Preservative treatment: Every spare part has preservative treatment, such as galvanized or sprayed anti-corrosion paint to adapt to severe environments, preventing rust and corrosion.

-

Easy to install.

-

Maintenance friendly.

Bolted crane rail clips structures:

Bolted crane rail clips mainly consist of seven sections: base, upper cover, wearing shaft, flat washer, bolts, nuts, and shims.

-

Base: Provide stable support, and fixes the track on the infrastructure through fixed device fixes.

-

Upper cover: Cover and protect the tracks, meanwhile providing extra chucking power to ensure the tracks’ stability.

-

Wearing shaft: Stand and disperse the track load and reduce the friction and wear between the tracks and the clips.

-

Flat washer: Used in bolt joints, increase the contact area to dispersive stress, ensuring connection’s fastness and stability.

-

Nuts: Used with bolts to provide tightening force.

-

Shims: Adjust the tracks' height and levelness, ensuring proper alignment of tracks.

About bolted crane rail clip material:

-

Wearing shaft: We specify uniformly adopt wear-resistant steel NM360 or NM400.

-

Base, upper cover, and shims: We support two kinds of material for your selection: Q235 or Q345 carbon steel, and 40Cr or 45# high-strength steel.

-

Flat washer and shims: We also have two kinds of material for your selection: Q235 or Q345 carbon steel, and 304 or 316 stainless steel.

Bolted crane rail clips correlation series is WJK series、SWJK series and HWJK series, please contact us for relevant parameters for the detailed parameters, except for the three series, we also have models: 2524/20, 4010/25, Oct-16.

The following are the detailed parameters:

|

Model |

2524/20 |

4010/25 |

Oct-16 |

|

Rail Height |

150 mm |

200 mm |

180 mm |

|

Rail Width |

130 mm |

150 mm |

140 mm |

|

Base Width |

250 mm |

300 mm |

280 mm |

|

Base Thickness |

24 mm |

25 mm |

20 mm |

|

Upper Cover |

20 mm |

25 mm |

16 mm |

|

Wearing Shaft |

16 mm |

18 mm |

16 mm |

|

Flat Washe |

30 mm |

35 mm |

32 mm |

|

Bolt Diameter |

20 mm |

25 mm |

20 mm |

|

Material |

Q235, Q345 |

Q235, Q345 |

Q235, Q345 |

|

Load Capacity |

120 kN |

180 kN |

150 kN |

|

Applicable |

-40°C to |

-40°C to +80°C |

-40°C to |

|

Surface Treatment |

Hot-dip |

Hot-dip Galvanizing, |

Hot-dip |

|

Applicable |

Indoor and |

Outdoor, medium |

Indoor and |

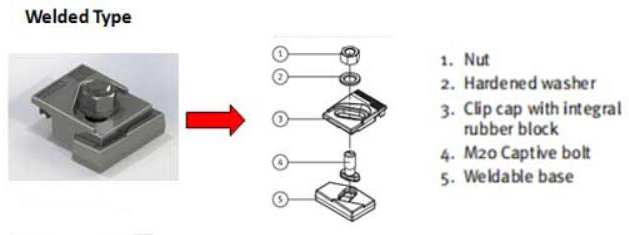

Welded Crane Rail Clips

Welded rail crane clips are a kind of track-fixing device that is permanently attached to the supporting structure (such as concrete or steel beams) through welding. Because of its fixed way, it has extremely high strength and stability, and to the benefit of reducing shake. Also, because of its features for permanent installation, it can greatly reduce the number of maintenance. They always show a great advantage in high-load, extreme weather conditions.

Welded rail crane clips Uses:

-

Heavy-duty crane rails: Used in dealing with heavy-duty and continuous operation environments, such as ports, steel mills, and mine cranes.

-

High-stress track system: Suitable for applying to high dynamic load and frequent use, provides powerful fixed solutions.

High-temperature environment: It’s well-behaved in a high-temperature environment, such as steel mills and foundries, and welded connection provides extra stability and safety.

Welded rail crane clips advantages:

-

High strength and stability: Welded rail clips provide excellent stability to stand with high dynamic load, very suitable for ports, steel, mines, etc. heavy-duty applications.

-

Permanent installation: Welded connections provide permanent solutions to ensure tracks keep rigid fixation during service life. It’s especially important in heavy-duty environments, dependability is crucial.

-

Reduce the number of maintenance: As there are no bolts or mechanical fasteners lost along with time, welded rail clips need less maintenance time than bolted crane rail clips.

-

Shock resistance: Rigid welded connections are advantageous for reducing shake, which is very beneficial to noise decline and reducing the abrasion of the tracks and the braced structure.

Welded rail crane clips structures:

Welded rail clips mainly consist of four sections: base plate, upper cover, wearing shaft, and weld joint.

-

Base plate: Provide stable support, and through weld fixed on the infrastructure.

-

Upper cover: Cover and protect the tracks to ensure the track's stability.

-

Wearing shaft: Stand and disperse the track load and reduce the friction and wear between the tracks and the clips.

-

Weld joint: Weld the base to the base structure to provide solid fixation.

About welded rail clips' material:

Except for the wearing shaft, we specify uniformly adopt wear-resistant steel NM360 and NM400. For the other parts, we support two kinds of material for your selection: 40Cr or 45# steel Carbon steel, NM360 or NM400 High-strength steel.

The following are the detailed parameters:

| Parameter | WJ38 | WJ50 | WJ60 | HW70 | HW80 |

| Rail Height (mm) | 38 | 50 | 60 | 70 | 80 |

| Rail Width (mm) | 38 | 50 | 60 | 70 | 80 |

| Base Width (mm) | 60 | 75 | 85 | 100 | 110 |

| Base Thickness (mm) | 8 | 10 | 12 | 14 | 16 |

| Cover Thickness (mm) | 4 | 6 | 8 | 10 | 12 |

| Wearing Shaft Diameter (mm) | 12 | 16 | 18 | 20 | 22 |

| Flat Washer Diameter (mm) | 25 | 30 | 35 | 40 | 45 |

| Bolt Diameter (mm) | M12 | M16 | M18 | M20 | M22 |

| Material | carbon steel | carbon steel | high-strength steel | high-strength steel | high-strength steel |

| Load Capacity (T) | 60 | 80 | 90 | 100 | 120 |

| Temperature Range (°C) | -20 to 60 | -20 to 80 | -20 to 81 | -30 to 90 | -30 to 91 |

| Surface Treatment |

galvanized, coating |

galvanized, coating |

galvanized, coating |

hot-dip galvanized, painting |

hot-dip galvanized, painting |

| Application Environment | Light industrial applications | Medium industrial applications | Heavy-duty applications | Extreme weather and heavy-duty applications |

Extreme weather and heavy-duty applications |

We provide:

●Customized design: We support customized specific models and specification crane rail clips to ensure our product perfectly fits your existing equipment.

●Technology support: We provide technology inquiry and support, including the choice of crane rail cranes, install guidance, and maintenance suggestions to ensure our guests use and maintain the crane rail cranes correctly.

●Quality guarantee: Provide high-quality crane rail clip products that meet international standards and customer-specific requirements.

●After-sales service: Provide comprehensive after-sales services, including product warranty, replacement parts, and repair services to answer guests’ technology support requirements timely.

●Delivery and distribution: Provide timely delivery services, and according to the guests’ requirements conduct safe and efficient product distribution to ensure that products arrive at designated locations on time.

Get your free quote today! Contact us now to find the best deals on crane rail clips!

- Rail Fasteners

- rail fastening system

- rail clip

- railroad spike

- Track bolt

- rail shoulders

- rail anchor

- rail clamp

- tie plate

- Rail Pad

- rail insulator

- rail plastic dowel

- other rail fasteners

- Railway Switch

- SKL series rail fastening system

- Chinese standard rail fastening system

- screw spikes

- Crane rail fastening system

- K type rail clip for Africa

- Hey-Back Rail Fastening

- rail fasteners for Mexican market

- Ss25 screw spike

- Ss35 rail sleeper screw spike

- Ss8 screw spike

- coach screw

- Crane Rail Clip

- Rail Joints (Fishplate)

- Steel Rail

- Railway Sleeper

rail clip

rail clip

rail joints

rail joints

Español

Español English

English