Analysis of Rail Fastening System: Part2

The rail fastening system is selected by various countries around the world according to national conditions, tradition, real situation of railway, they are different and formed. We have writen the chinese standard rail fastening system before, today AGICO Rail will analyze the international standard rail fastening system.

France

France was one of the first countries in the world to use elastic fasteners. In the 1950s, RN-type rail fasteners were used to use rail clip as a rail fastener. Later, with the development of high-speed railways, clip in the form of double arches was used as a rail fastener. This is the Nablus fastener. RN fasteners and Nablus fasteners are promoted in some countries in Africa and Southeast Asia. Japan is also a country that uses rail clip as a rail fastener.

Japan

In the early 1960s, Japan introduced the French RN fasteners, and it was promoted and used in the Tokaido Shinkansen, called the 102-type rail fasteners. With invent of slab track, Japan has developed straight-type 4, straight type 5 and straight type8 fasteners for slab track, all of which use clips as the fasteners for rails.

When the elastic rail clip is pressed, the bending property of the material is mainly utilized, the processing is relatively simple, and the cost is often low. However, since the hole is processed to meet the bolt tightening requirement, stress concentration is likely to occur at the portion, and the maximum bending moment is precisely the maximum portion of the section weakening, so that damage is likely to occur, and the buckle pressure and elasticity of the fastener are insufficient. When the elastic clip fastener is working, both the bending deformation property and the torsional deformation property of the material are utilized, so the elasticity is generally better, and substantially no section is weakened, so the material utilization efficiency is high. The famous Pandrol fasteners and Vossl oh fasteners all adopt rail clips.

UK

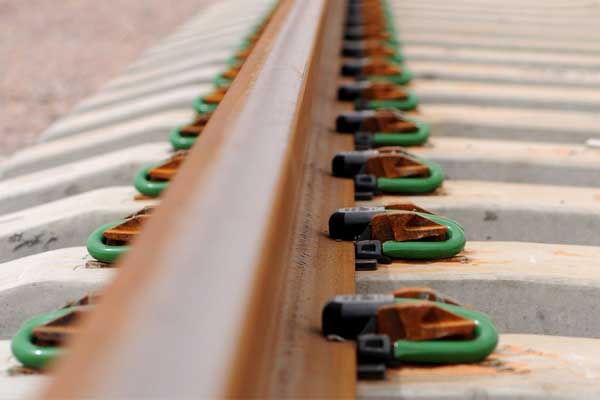

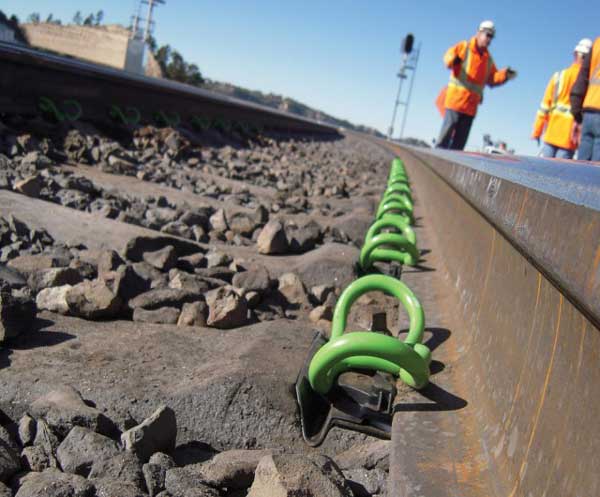

British Pandrol fasteners are the most famous and influential rail fasteners in the world. They are applied in dozens of countries and regions. All high-speed railways in Belgium, Spain, Italy, South Korea and the United States fully or partly use Pandrol fasteners. Pandrol fasteners are now also heavily used in high-speed railroads in Japan and France. Pandrol fasteners are non-shoulder, non-bolt fasteners, with advantages of high buckle pressure (not less than 11 kN) and good elasticity (elastic deformation not less than 12 mm), especially due to the elimination of the concrete shoulder, thus eliminating the possibility of rail gauge increase caused by the sliding of the rail cant under the action of the lateral force, so the ability to maintain the rail gauge is strong. In addition, the way of bolting is eliminated, which reduces the workload of rail fastener maintenance. Chinese standard type III rail fasteners are similar to e-clip Pandrol fasteners.

Due to the small adjust range of rail height and rail gauge of the e-clip fasteners, the range of use is affected. In response to these two problems, Pandrol developed Fast clip fasteners based on the advantages of the e-clip fasteners.

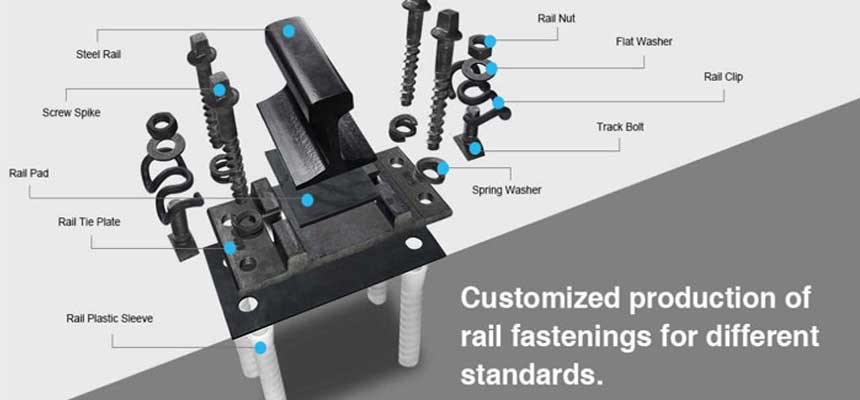

Fast clip fasteners are still no-shoulders, no bolts, and less maintenance fasteners. Fast clip consist of a bottom tie plate, rail bolts and rail sleeves, gauge block, rail pad and rail clips. The bottom plate is fixed on the railway sleeper by an rail sleeve embedded in the sleeper and corresponding rail bolts, and the upper surface of the bottom plate is a structure for fastening the elastic clip fasteners, and is a self-locking fastening system. As long as the rail clip is installed in place on the bottom plate, the designed buckle pressure is reached. The elastic clip is similar to the ω shape, and the pressure of the single elastic clip is 12. 5 kN, which is installed perpendicular to the direction of the rail and hard to fall off. The rail plastic sleeve is an engineered "plastic/metal" composite bushing, which is embedded in the sleeper and is used for screwing the anchor bolt fastener together with the sleeper. The fastener is pre-installed on the sleeper at the factory. Simply push the pre-installed clips into the direction of the rails so that the clips are in place and easy to install. The fast clip fasteners can all be installed mechanically. The fastener adjusts the height of the rail by inserting the pad under the bottom plate, and the maximum height is 27 mm. The adjustment of rail gauge is to loosen the anchor bolt properly, then move the bottom plate laterally along the slot of the screw hole, and then tighten the bolt. The maximum adjustment is ± 12 mm.

German

The German high-speed railway uses Vossloh rail fasteners with shoulders and bolts. Vossl oh rail fasteners consist of five parts: rail clip, gauge blocks, rail bolts, rail plastic sleeves and elastic cushions. An elastic rail pad is placed between the rail and the sleeper bearing groove, and the lateral position of the rail is fixed by the gauge block. The elastic clip is pressed on the gauge block, and the elastic clip is of the SKL14 type of ω shape, which is bolted and embedded in the sleeper. The rail plastic sleeve is matched with the fastening elastic clip, and the gauge blockmaterial is engineering plastic, which not only maintains the rail gauge but also acts as insulation. The rail clip design has a buckle pressure of 11 kN, a spring range of 14 m, and a cushion pad static stiffness of 70 kN/mm. The way to adjust the height of the rail is to loosen the bolt, insert the height adjustment plate under the rail, and then tighten the bolt with a maximum height adjustment of 26 mm; the adjustment gauge is ± 10.

- Rail Fasteners

- rail fastening system

- rail clip

- railroad spike

- Track bolt

- rail shoulders

- rail anchor

- rail clamp

- tie plate

- Rail Pad

- rail insulator

- rail plastic dowel

- other rail fasteners

- Railway Switch

- SKL series rail fastening system

- Chinese standard rail fastening system

- screw spikes

- Crane rail fastening system

- K type rail clip for Africa

- Hey-Back Rail Fastening

- rail fasteners for Mexican market

- Ss25 screw spike

- Ss35 rail sleeper screw spike

- Ss8 screw spike

- coach screw

- Crane Rail Clip

- Rail Joints (Fishplate)

- Steel Rail

- Railway Sleeper

rail clip

rail clip

rail joints

rail joints

Español

Español English

English