7 Requirements For Rail Fastening System Of Passenger Railway

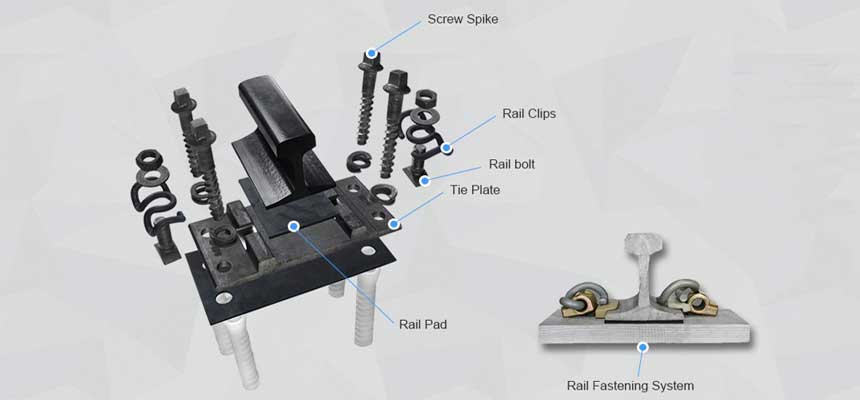

Railway fastening system is used to fix steel rail and railway sleeper, it usually consist of rail clips, tie plate, screw spike, rail pad, rail insulator, rail plastic dowel, etc. There are various types of rail fastening system for meeting different requirement of various railway section, such as SKL rail fastening system, E-clip fastening system, KPO fastening system, Nabla fastening system.

Due to the passenger dedicated line is mainly aimed at comfort and safety, the passenger dedicated line has no need for a single sub-structure. It involves various structural foundations such as bridges, tunnels and subgrades, and must meet operating conditions. The requirements of the following key technical issues of the fastener system need to be considered.

Good vibration damping performance

The ballastless track fasteners should have better elasticity than the ballasted track fasteners, but the elasticity cannot be increased without limitation. Otherwise, the rails will be tilted too much when the train passes, and the dynamic gauges will affect the smoothness. There are two key technologies to be studies, firstly, matching the stiffness of the rail fastening system and the track stiffness. Secondly, both lower stiffness of rail fasteners and driving safety are all considered.

High insulation performance

According to the requirements of the track circuit, the rail fastening system has high insulation performance not only under dry conditions, but also in case of heavy rainfall. It requires special technical measures to improve the water film resistance of the rail fastening system.

The versatility of rail fastening system on continuous welded rail

Due to the requirement of continuous welded rail laying, the fastening system in the tunnel or on the roadbed should have sufficient anti-climbing resistance. In the normal situation, the greater the anti-climbing resistance is, more beneficial to the continuous welded rail, so the elastic clip with large buckle pressure is often used to buckle the rails. In order to meet the requirements of laying continuous welded rail, the bridge fastener system usually adopts a small resistance elastic fastener, in other word, use rail clip with a small buckle pressure and a composite pad with a lower friction coefficient to buckle the rail. Therefore, for the rail fastening system installing, a rail clip with large buckle pressure or small buckle pressure are both available.

The versatility of the rail fastening system on various ballastless track

Various ballastless track structures are different, but the rail fastening system is versatile from the perspectives of design, construction and operation management. Whether the sleeper buried ballastless track or the slab ballastless track, the rail fastening system should be installable, that is, the rail fastening system can accommodate a variety of different types of ballastless track structures.

Deduction of buckle pressure and fatigue life

The stiffness decrease of the rail pad under the track means that the train has a large deformation when it passes, and the dynamic deformation of the front end of the elastic clip is increased, which require the elasticity and fatigue performance of the elastic clip. The buckle pressure reductions of rail clip under the lower stiffness rail and fatigue life are two problems.

Reliable connection between the rail fastening system and the foundation

The ballastless track fastener generally adopts an elastic split fastener with an iron tie plate. According to the functional requirements, the iron tie plate is fastened to the foundation by the anchor bolt and the pre-embedded insulating sleeve (also called plastic insulating dowel) in the concrete foundation. According to the previous engineering practice, the strength and fatigue life of the embedded parts in the concrete foundation are weak links. Taking measures to effectively improve the strength and fatigue life of the pre-embedded insulating dowel is one of the problems to be solved.

Fewer spare parts and convenient operation mode

Fewer spare parts and convenient operation mode achieve high and low position adjustment of the rail. Summarize the practical experience of ballastless track engineering, the rail height and position adjustment amount is large and fine adjustment is required. Therefore, the rail fastener system structure adopted should have a mode with less spare parts and convenient operation to adjust the height and the positions of the rail. When making the left and right position adjustment, try not to replace the parts, and the adjustment mode is preferably stepless adjustment.

- Rail Fasteners

- rail fastening system

- rail clip

- railroad spike

- Track bolt

- rail shoulders

- rail anchor

- rail clamp

- tie plate

- Rail Pad

- rail insulator

- rail plastic dowel

- other rail fasteners

- Railway Switch

- SKL series rail fastening system

- Chinese standard rail fastening system

- screw spikes

- Crane rail fastening system

- K type rail clip for Africa

- Hey-Back Rail Fastening

- rail fasteners for Mexican market

- Ss25 screw spike

- Ss35 rail sleeper screw spike

- Ss8 screw spike

- coach screw

- Crane Rail Clip

- Rail Joints (Fishplate)

- Steel Rail

- Railway Sleeper

rail clip

rail clip

rail joints

rail joints

Español

Español English

English